Reservoir / Sub-Surface

Our company focus is on developing and applying innovative technology to improve surveillance, appraisal and production of oil and gas with additional application to CO2 storage reservoirs.

Our technology has the potential to disrupt current practices in oil/gas production and advance reservoir surveillance so that our clients can achieve real efficiencies and cost savings while meeting their desired social, safety and environmental goals.

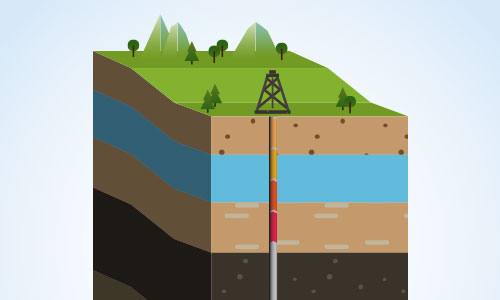

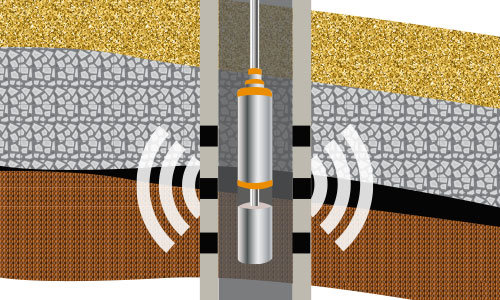

Saturation mapping and monitoring.

An improved understanding of fluid saturation and its spatial and temporal change can have a dramatic effect on production. Based on the density contrast that exists between the hydrocarbon (i.e., oil and gas) or CO2 and water - with the straightforward linear relationship between saturation and density change - the deep sensing borehole microgravity survey provides a highly effective means to map the fluid saturation changes during the enhanced oil recovery (EOR) process. The ability of gravity measurements to sense through casing makes this technology superior to many other approaches. With a rich time-lapse three-component micro gravity data set, inversion-based history matching (constrained by gravity data) uncertainties can be reduced and current saturation mapping enhanced. Repeat monitoring surveys provide the potential to update the static reservoir model more frequently than currently possible.

Flood front prediction (sweep/water injection management) and monitoring water coning either in vertical or horizontal wells.

Understanding the flow direction of injected fluid or detecting the early breakthrough of water coupled monitoring general fluid movement in the reservoir can significantly increase a reservoirs ultimate production, through reduced uncertainty and hence better management. Three-axis borehole time-lapse microgravity measurement in one or more wells will help assess water front movement and direction, or avoiding coning through the field and lead to improved production. A 1% increase in recovery through improved water front surveillance can generate upwards of a billion dollars in additional revenue from a super giant field.

HYBRID 4D seismic/4D gravity monitoring

Combining these more frequent repeated (time-lapse) borehole microgravity surveys with and in between a conventional 4D seismic survey will decrease the overall cost and increase the monitoring frequency of these costly surveys. Both are complementary and microgravity surveys can be incorporated into existing 4D seismic workflow models cost effectively.

By-Passed hydrocarbon (Oil and Gas) analyses

Understanding where missed (by-passed) hydrocarbons may be located and better constraining these could add significantly to reserves and ultimate production. Using the contrasts in densities of rocks filled with hydrocarbon (oil/gas) versus water coupled with the deep sensing nature of the gravity measurement, three-axis microgravity measurement can help identify areas of potential ‘missed’ or by-passed hydrocarbon even located away from the borehole.

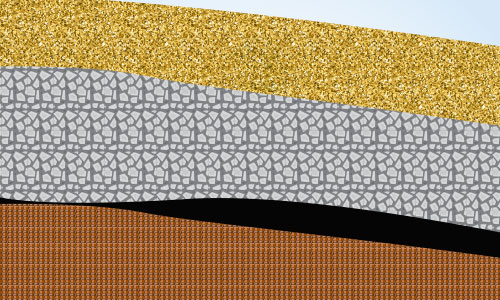

Thin-bedded pay identification

Just as in the case of by-passed hydrocarbon identification, reserves may be increased in zones where current logging technology fails to identify thinly bedded hydrocarbon and non-hydrocarbon sequences. With sensitive borehole gravity measurements, using the contrast in density between hydrocarbon bearing rocks (oil/gas) and non-hydrocarbon bearing non-reservoir rocks (shales and silts), it will be possible to ascertain even ‘thin-bedded’ formations that other measurements may fail to recognize, even located away from the borehole.

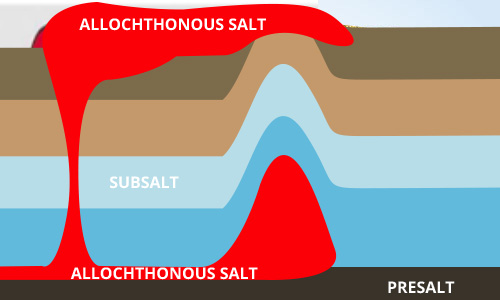

Sub-salt Mapping / Mapping salt domes

Current sub surface imaging methods such as seismic surveying can have big issues imaging the detail of reservoirs that occur proximal to or directly below salt layers or salt domes. Gravity, due to density contrast of salt and a surrounding reservoir fluids is a potential mapping tool for salt prone areas such as Brazil and Gulf of Mexico.

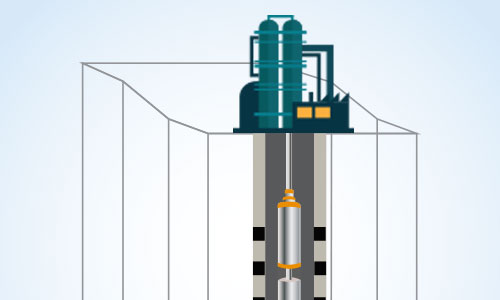

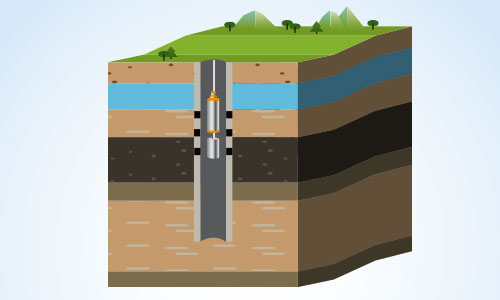

Permanent in-hole monitoring and smart well

Deploying an array of microgravity sensors permanently within a well completion could lead to a new level of reservoir surveillance. On-demand or constant data acquisition will supplement and improve on-going management of reservoir fluid fronts and water coning and early breakthrough may be minimized.

The combination of deep reading, surface readout, micro-gravity sensors plus hydraulic or electrically controlled sleeves will deliver a truly smart well with the ability to choke zones and thus avoid water or gas breakthrough for as long as possible. Our technology innovation and research will look at how this technology can be deployed in these emerging permanently instrumented wells.

CO2 storage, plume location, movement and surveillance

To overcome the limitations of existing monitoring of CO2 in storage reservoirs, near real-time borehole microgravity measurements may help to resolve the dynamic advance of CO2 plume fronts and other dynamic changes occurring within the storage reservoir. The potential exists to measure density changes associated with injected CO2 as it substitutes fluids already present in the rock and thus provide a means to evaluate the total amount of injected CO2. It will also supplement or provide a cost effective alternative for the volumetric definition provided by current available seismic surveys.